-

Aerospace,aircraft

5G/4G, wireless communication, digital TV, mobile phone, fiber optic communication, communication equipment, radio frequency, Bluetooth, radio.

Cryptanalysis System

Cyber counterintelligence system

Command and control system

Automatically search for interference systems

AMRAAM-advanced medium-range air-to-air missile

ECCM-Electronic Countermeasures

IADS-Integrated Air Defense System

AWACS-Airborne Early Warning and Control System

ASRAAM-advanced short-range air-to-air missile

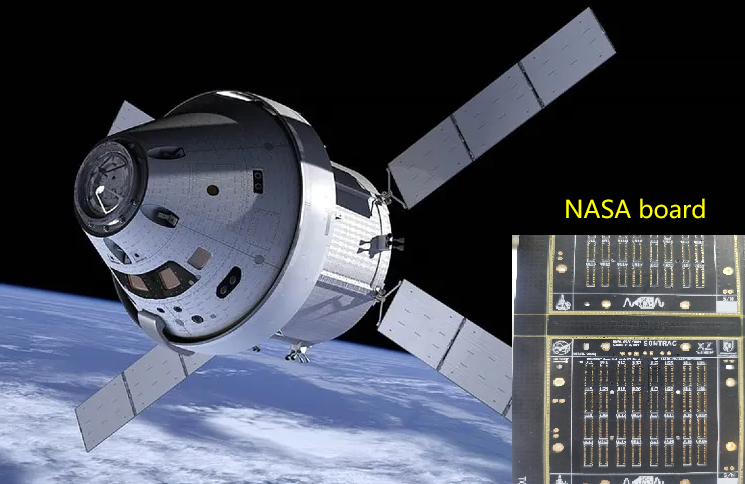

NASA board made by Storm Circuit

-

Amazon Telecom PCB made by Storm Circuit

5G/4G, wireless communication, digital TV, mobile phone, fiber optic communication, communication equipment, radio frequency, Bluetooth, radio.Wireless communication systems,two way radio,High speed servers and routers.Electronic data storage devices..Land wired communication systems.Digital and analog broadcasting systems.Signal boost systems.Security technology and information communication systems

-

3D printing, mobile medical, internet +, medical equipment, wearable, telemedicine,Medical equipment,

Blood glucose meter

Electrocardiograph

Heart monitor

Thermometer

CT scanning system

EMG activity system

Infusion control

Peristaltic infusion technology

Sphygmomanometer

Magnetic resonance imaging (MRI) scanning system

X-ray computed tomography (CT) scanning system

Gas analyzer

Digital cell counting device

Pacemaker analyzer

Ultrasonic equipment

Laser treatment instrument

Liquid level controller

Nerve stimulation device

Digital temperature monitor

Ear, Nose and Throat (ENT) diagnostic equipment

Medical data transmitter

Gas chromatograph

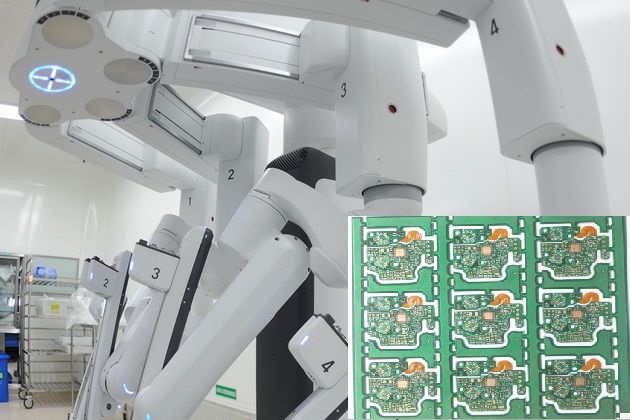

4 Layer rigid-flex board made by Storm Circuit

-

Many heavy copper PCB used in Automotive.Electric vehicles, automotive electronics, new energy vehicles, car networking, automotive electronics, body electronics, powertrain, automotive safety.

ECL/ECU control module

Anti-lock braking system

Digital display

Power relay

Dashboard

Sensor

Radar

Audio system

DC/AC power converter

Engine timing system

Electronic mirror control

Battery control system

airbag

LED lighting system

Turn to

Engine control system

Air Conditioning System

ABS

16 layer Automotive mother PCB made by Storm Circuit

-

10 layer 4.85mm thickness PCB made by Storm Circuit

Electric vehicles, automotive electronics, new energy vehicles, car networking, automotive electronics, body electronics, powertrain, automotive safety.

Amplifiers

Analog meters

HVAC Controls (Heating)

Circuit protection

Instrumentation

Digital meters

Indicators & Displays

Line conditioners

Electro-mechanical controls

Industrial controls

Microprocessors

Power line monitors

Potentiometers

Power monitoring

Safety & signaling

Solid state relays

Electro-mechanical controls

Indicators & Displays

Overload relays

Oscilloscopes

Microprocessors

Battery systems

Fiber optics

We are very proud of our PCBs used for NASA ,although they are just some prototypes, designed by US university. highly advanced electronic devices or gadgets for any aerospace product, rapid turn prototypes with effective engineers play a vital role in making the device successful. There are many types of PCBs used in the manufacture of heavy aerospace equipment.

Military and aerospace are two industries that utilize the most advanced electronic applications. The systems used in these fields require precision and superiority in terms of performance. There are several factors that affect the design of these PCBs:

Materials of Construction: PCB components used in military and aerospace applications must be strong enough to withstand high temperatures. Generally, high-temperature laminates (such as aluminum and copper substrates) are used in PCBs for aerospace and military applications. Today, anodized aluminum is used to minimize the effects of thermally induced oxidation. Various aluminum substrates combined with thermally conductive pre-nails are known to have weight advantages.

Reduce electromagnetic induction and attenuation: In the PCB assembly process for military and aerospace applications, the strands are immersed in hot melt solder, dried and cured. Dry welding can increase the dry strength. It helps to improve the conversion of multiple stranded wires into solid wires, eliminate air gaps, and stabilize airflow. This helps reduce the influence and attenuation of electromagnetic interference (EMI). Moreover, it also increases the reliability of aviation/military PCBs by approximately 2% to 5%.

Conformal coating and surface treatment: Most aerospace and defense applications are under extreme environmental conditions, such as continuous exposure to moisture, water, extreme temperatures and humidity. Therefore, the application of an appropriate conformal coating becomes important. Generally, consider using acid-based sprays for conformal coatings. Other types of surface treatments and coatings include ENIG, HASL, immersion silver, etc.

Here are some advanced aerospace and military applications that utilize high-quality PCBs:

-

Cryptanalysis System

-

Cyber counterintelligence system

-

Command and control system

-

Automatically search for interference systems

-

AMRAAM-advanced medium-range air-to-air missile

-

ECCM-Electronic Countermeasures

-

IADS-Integrated Air Defense System

-

AEW&C-Airborne Early Warning and Control

-

AWACS-Airborne Early Warning and Control System

-

ASRAAM-advanced short-range air-to-air missile

Automotive electronic products are import market for PCB. For automotive printed circuit boards, reliability is of the utmost importance. They need to survive extreme environmental conditions and vibrations without any setbacks in performance. Automotive PCBs must meet strict thermal cycle tests, thermal shock tests, and temperature and humidity tests before they are considered. The circuit board must suppress conductive anode filament (CAF) defects in the dielectric. CAF can cause a short circuit between the copper clad laminate (CCL) and the conductive traces.

In addition, it is expected that the circuit board will be fully operational in the long term. Heat resistance and service life make automotive printed circuit boards completely different from other printed circuit boards. PCB manufacturers must comply with the ISO/TS 16949 standard, which is based on the ISO 9001 automotive standard. VictoryPCB is a professional manufacturer of automotive circuit boards in China who own ISO/TS 16949 certificate. Its products include: car navigation circuit boards, car instrument circuit boards, car charger circuit boards, and new energy car circuit boards.

Types of Automotive PCBs

Printed circuit boards has many applications in countless sectors ranging from healthcare to electronics, but their impart is perhaps the most evident in the automotive industry. So what are these special types of PCBs made up of? Let's have a look.

The LED boards made of aluminum substrate since they require heat dissipation. They can be found in car indicators, headlights, and brake lights.

Automotive applications, in particular, carry a number of advantages, not only in the usual arena of reliability but even more so for the weight savings that a flex PCB offers compared with a standard PCB and wiring harness. Flex PCBs greatly reduce the labor involved in manufacturing a traditional automotive wiring harness. And the inherent resistance of flex PCBs to vibration makes them ideal for the harsh environment inside a motor vehicle.

The Automotive printed circuit boards employ thicker copper (Cu) in the outer and inner layers of the boards. These heavy copper boards are preferred over the regular ones since they can withstand high temperature, high frequency, and high current variations. The regular boards display a copper thickness of around 25µm to 50µm. Whereas, the heavy copper PCBs will be 150µm to 200µm thick. These boards are implemented in safety and signaling systems.

Automotive Printed Circuit Board Applications

-

ECL/ECU control module

-

Anti-lock braking system

-

Digital display

-

Power relay

-

Dashboard

-

Sensor

-

Radar

-

Audio system

-

DC/AC power converter

-

Engine timing system

-

Electronic mirror control

-

Battery control system

-

airbag

-

LED lighting system

-

Turn to

-

Engine control system

-

Air Conditioning System

-

ABS

In recent years, the medical industry has attached great importance to PCB assembly and manufacturing processes. For every medical project, PCB manufacturing requires high-end customization. Whether it is high, medium or small batch PCB production, PCB assemblers must continue to develop in chemical and electroplating processes, pressing, wiring and drilling processes under high temperature/vacuum in order to obtain high yields in mass production. The medical market also points to fierce competition on how to make devices compact, multifunctional, user-friendly and cost-effective.

Manufacturing Trends for Medical Grade PCBs

The current industrial production revolution, or Industry 4.0, emphasizes communications and software to improve manufacturing speed and efficiency. To ensure optimal medical grade PCBs, be sure to incorporate the standards described below that have emerged from this new industrial paradigm.

-

Ensure Design Intent: The best way to incorporate design intent throughout your board build process is to partner with your CM early in the development process.

-

Employ Digital Twin Technology: Simulation has long been used to prevent waste and mitigate development costs. For PCB manufacturing, digital twin technology encapsulates this objective and identifies errors or potential errors before the first board is spun.

-

Open and Transparent Collaboration: Establish and utilize open and transparent communication with your CM from the start so that your medical grade PCB becomes a collaboration between you and your CM.

-

Optimize DFM and DFA Utilization: Right-first-time (RFT) manufacturing is essential to optimize medical PCBA development. To meet this high yield rate objective, make design choices that utilize your CM’s DFM and DFA rules and guidelines.

-

Agile Manufacturing Process: By initiating agile processes, board builders can incorporate design changes iteratively with minimal manufacturing disruptions.

-

Types of PCBs for the Medical Industry

-

Rigid pcb or flexible circuit boards with magnetic flux telemetry communication are highly used to manufacture medical devices such as cardiac devices, pacemakers and ICDs. Multi-layer flexible PCB has a very high application in neural simulation implants, which requires large-scale miniaturization. For hearing aid devices and infusion drug pumps, a rigid/flexible PCB is more preferred because it has a flexible coil that facilitates the communication mechanism. In order to obtain durable and safe electronic solutions, customized PCBs for in-vivo and in-vitro diagnostic applications adopt mature designs to meet customers' unique specifications.

They are many rigid-flex PCB used in medical equipments.

Medical Applications Utilizing Printed Circuit Boards

There are so many applications of printed circuit boards in the medical field, and the list is continually growing. You will find PCBs in medical devices like:

-

Blood glucose meter

-

Electrocardiograph

-

Heart monitor

-

Thermometer

-

CT scanning system

-

EMG activity system

-

Infusion control

-

Peristaltic infusion technology

-

Sphygmomanometer

-

Magnetic resonance imaging (MRI) scanning system

-

X-ray computed tomography (CT) scanning system

-

Gas analyzer

-

Digital cell counting device

-

Pacemaker analyzer

-

Ultrasonic equipment

-

Laser treatment instrument

-

Liquid level controller

-

Nerve stimulation device

-

Digital temperature monitor

-

Ear, Nose and Throat (ENT) diagnostic equipment

-

Medical data transmitter

-

Gas chromatograph

Printed Circuit Boards are extremely useful in the telecom industry. Many telecommunication devices with electronic components are supported under the help of high-end PCBs. VictoryPCB provides printed circuit board assembly and telecom PCB fabrication services for a range of telecom products to meet the industry’s diverse needs.

Telecommunications Printed Circuit Board Applications

Communication is the most important downstream application field of PCB. PCB has a wide range of applications in various aspects such as wireless network, transmission network, data communication and fixed network broadband, and it is usually added value such as backplane, high-frequency high-speed board, and multi-layer board. Higher product. 5G is the next generation mobile communication network, and there will be a large amount of infrastructure construction demand by then, which is expected to greatly boost the demand for communication boards. Here are the most common applications of the telecommunication industry that make efficient use of PCBs:

Flexible Circuits are intended to provide a flexible interconnect so that it can move, curve or bend in installation. These circuits are great when space is limited or movement of the circuit is required. Other benefits of using flexible PCBs include enhanced capabilities and reliability.

The PCB demand for communication equipment is mainly high-multilayer boards (8-16 layer boards account for about 35.18%), and there is a demand for packaging substrates of 8.95%; the PCB demand for mobile terminals is mainly concentrated in HDI and flexible boards And package substrate.

Telecommunications Printed Circuit Board Applications

-

Wireless communication systems

-

Mobile phone tower systems

-

Telephonic switching systems

-

PBX systems

-

Industrial wireless communication technology

-

Technology for commercial phones

-

Video conferencing technologies

-

Communication technology used in space

-

Cell transmission and tower electronics

-

High speed servers and routers

-

Electronic data storage devices

-

Mobile communication systems

-

Satellite systems and communication devices

-

Video collaboration systems

-

Land wired communication systems

-

Technology for commercial phones

-

Digital and analog broadcasting systems

-

Voice over Internet Protocol (VoIP)

-

Signal boost systems (online)

-

Security technology and information communication systems

PCB requirements in the communications field can be divided into sub-fields such as communications equipment and mobile terminals. Among them, communication equipment mainly refers to the communication infrastructure used for wired or wireless network transmission, including communication base stations, routers, switches, backbone network transmission equipment, microwave transmission equipment, fiber-to-the-home equipment, etc.

Nowadays, the demand for industrial PCBs due to production process of PCBs has gone up due to growth in the industrial electronics market. As one of the leading electronic printed circuit board manufacturers, Our high quality PCBs products are widely used in industrial electronics. We are responsible for achieving maximum precision and perfection in our PCB design. Our PCBs can survive the harsh industrial environment. One of the main advantages of the printed circuit boards we design is that they are corrosion resistant.

Types of PCBs for Industrial Electronics

Rigid PCBs:Rigid PCBs are commonly used in electronics that provide strength to the circuits, make them rigid and prevent them from twisting.

Flexible circuit boards:Also known as flex circuits, they are made from flexible materials such as plastic, which can bend. This makes the mounting of components easy. Also, it helps reduce the complexity of the design by reducing the need for excess wiring and connectors.

Single-Sided PCBs:Also known as single-layer PCB, Single-sided means that the circuitry and the parts and components are placed only on one side of the board, meaning that this type of board is best suited to simple electronics.

Here are a few application areas of industrial electronics PCBs:

-

Amplifiers

-

Analog meters

-

HVAC Controls (Heating)

-

Circuit protection

-

Instrumentation

-

Digital meters

-

Indicators & Displays

-

Line conditioners

-

Electro-mechanical controls

-

Industrial controls

-

Microprocessors

-

Power line monitors

-

Potentiometers

-

Power monitoring

-

Safety & signaling

-

Solid state relays

-

Electro-mechanical controls

-

Indicators & Displays

-

Overload relays

-

Oscilloscopes

-

Microprocessors

-

Battery systems

-

Fiber optics