HDI PCB---High density interconnects

Printed Circuited Boards

What is an HDI PCB?

-

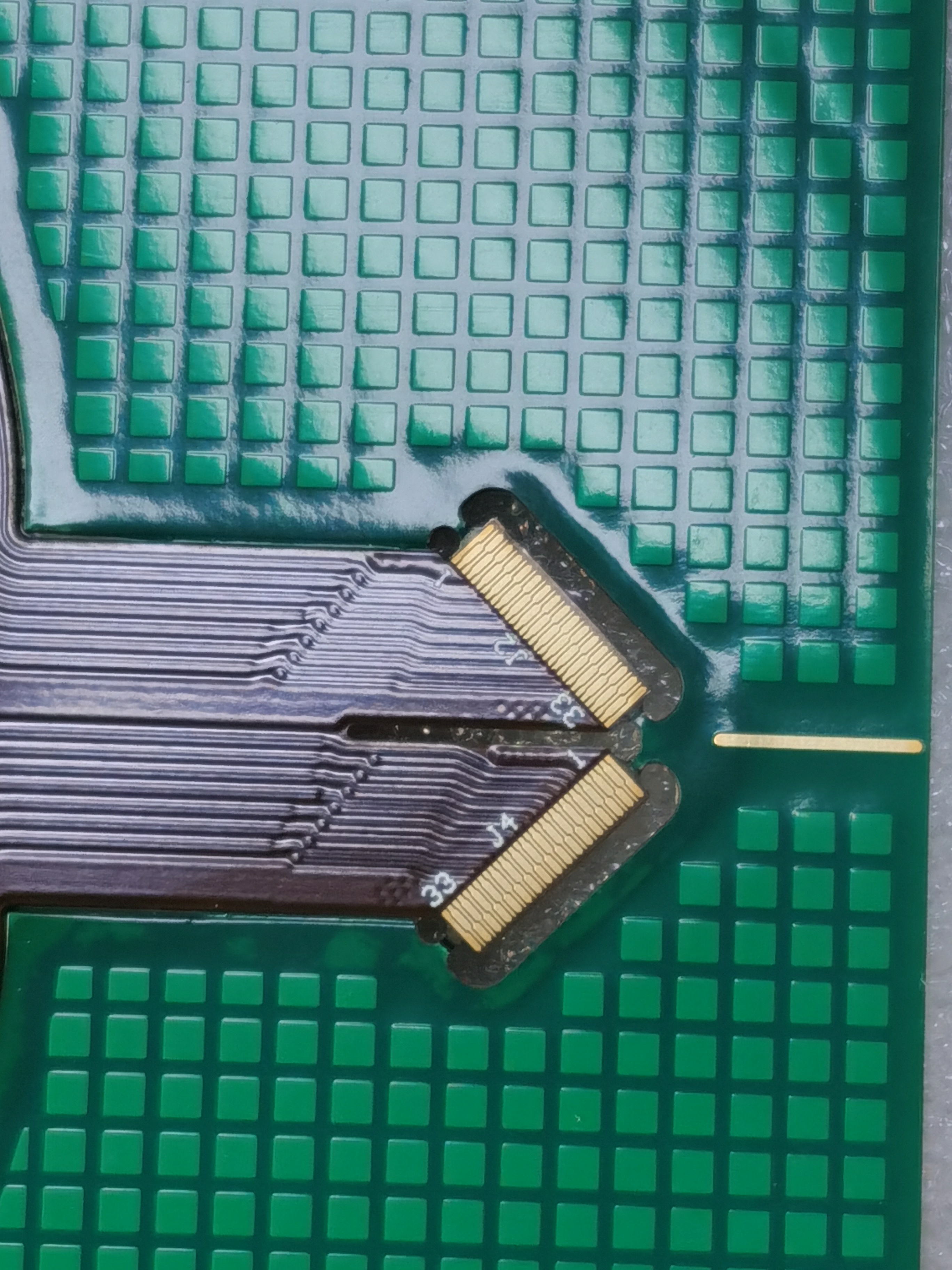

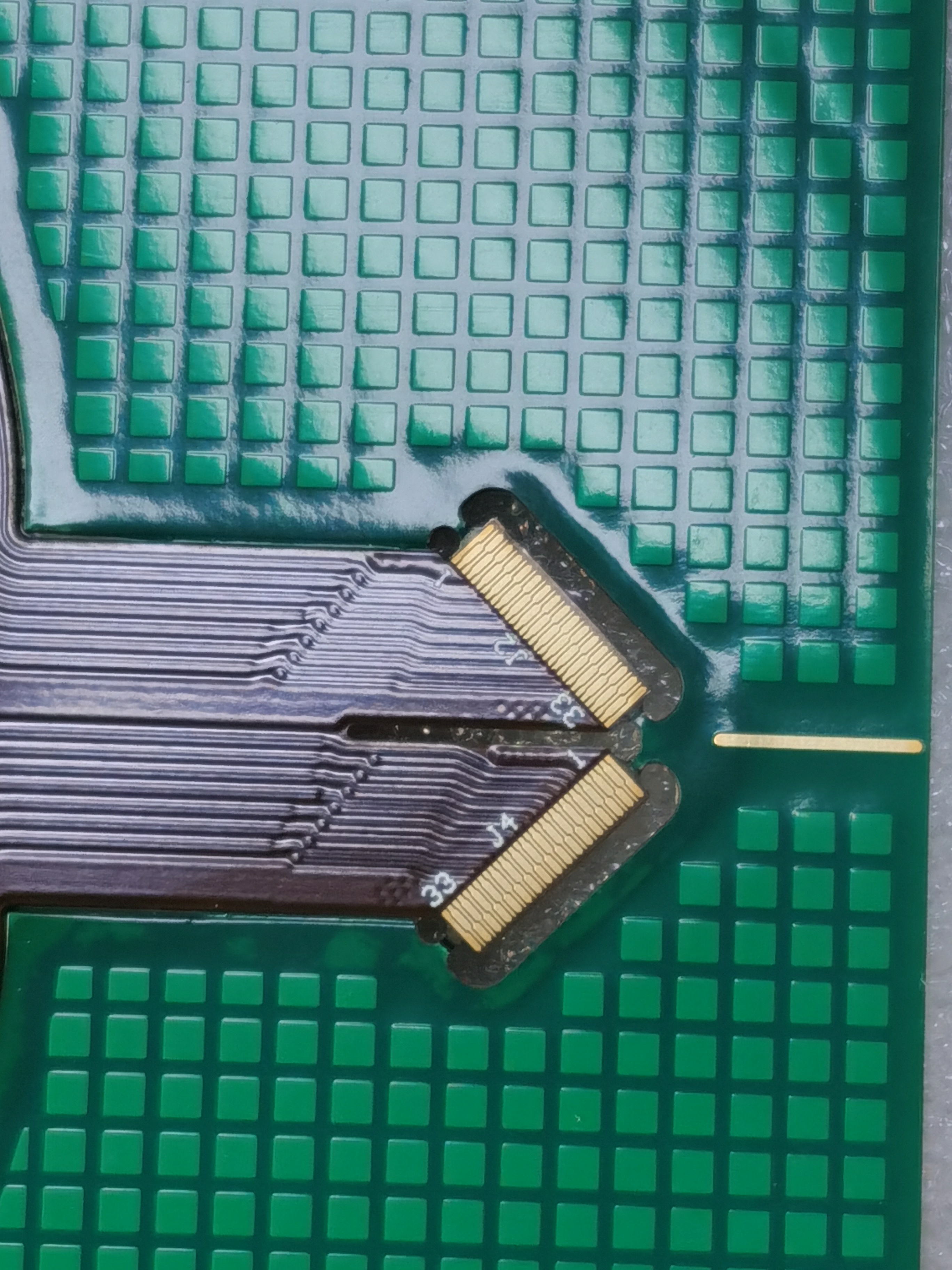

4 layer rigid-flex PCB with HDI design

¥ 0.00Buy now

-

4 Layer HDI PCB with 0.38mm pitch BGA

4 Layer HDI PCB with 0.38mm pitch BGA

Min hole:0.15mm

Min trace/space: 0.076/0.0/76mm

0.38CSP

Blind Vias:L1-L2

Via in pad, POFV (Plated over filled vias)

4 layer 1.0mm Laser drilling¥ 0.00Buy now

-

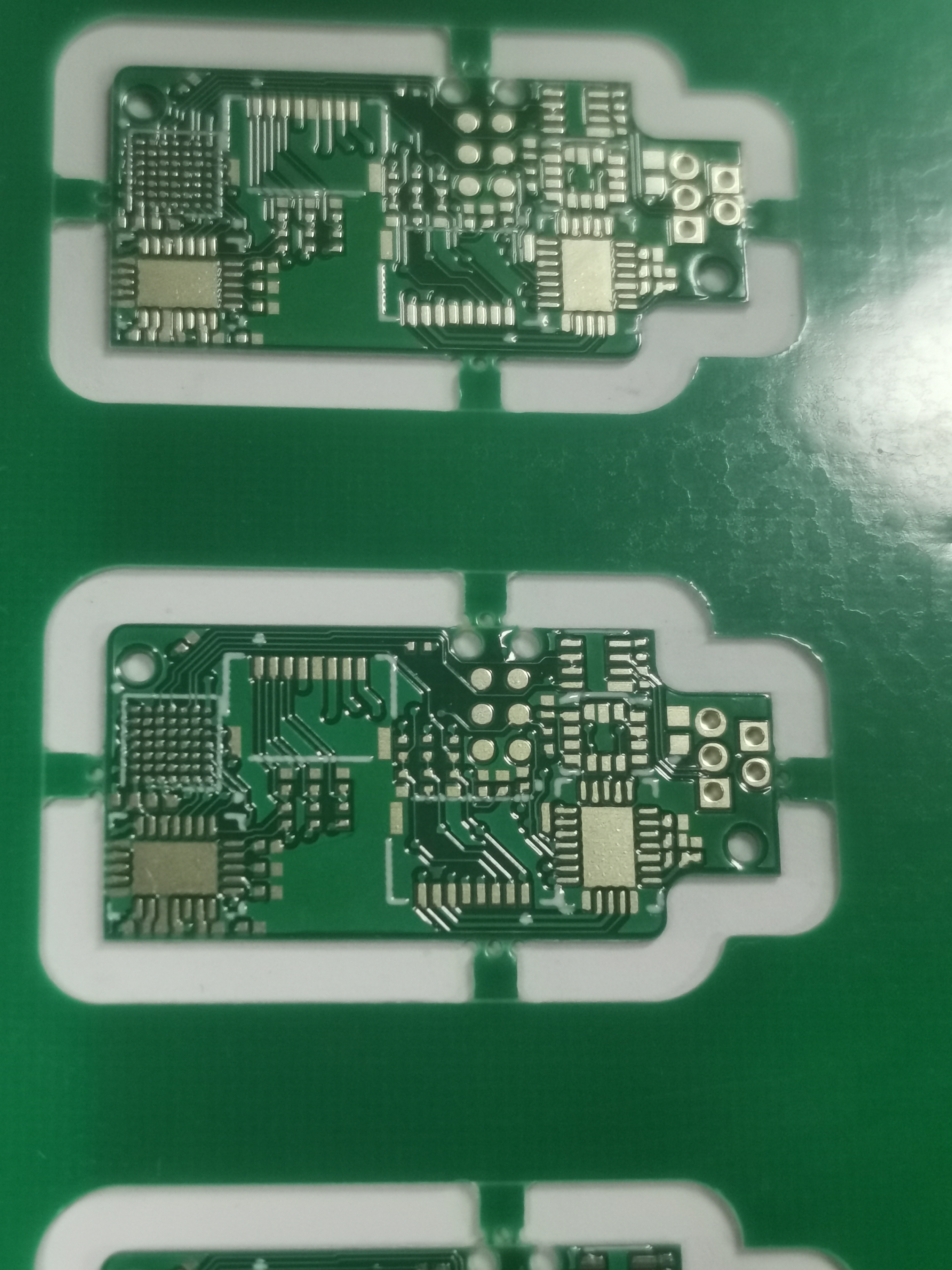

Quick Turn HDI PCB--shipping in 5 days

Two designs,4 layer HDI PCB,0.4mm pitch BGA¥ 0.00Buy now

-

4 layer HDI with 0.4mm,shipping in 5 days.

4 layer HDI

HDI:L1-L2,L1-L3,

Via in pad

Half hole plating

Quick Turn shipping in 5 days.¥ 0.00Buy now

-

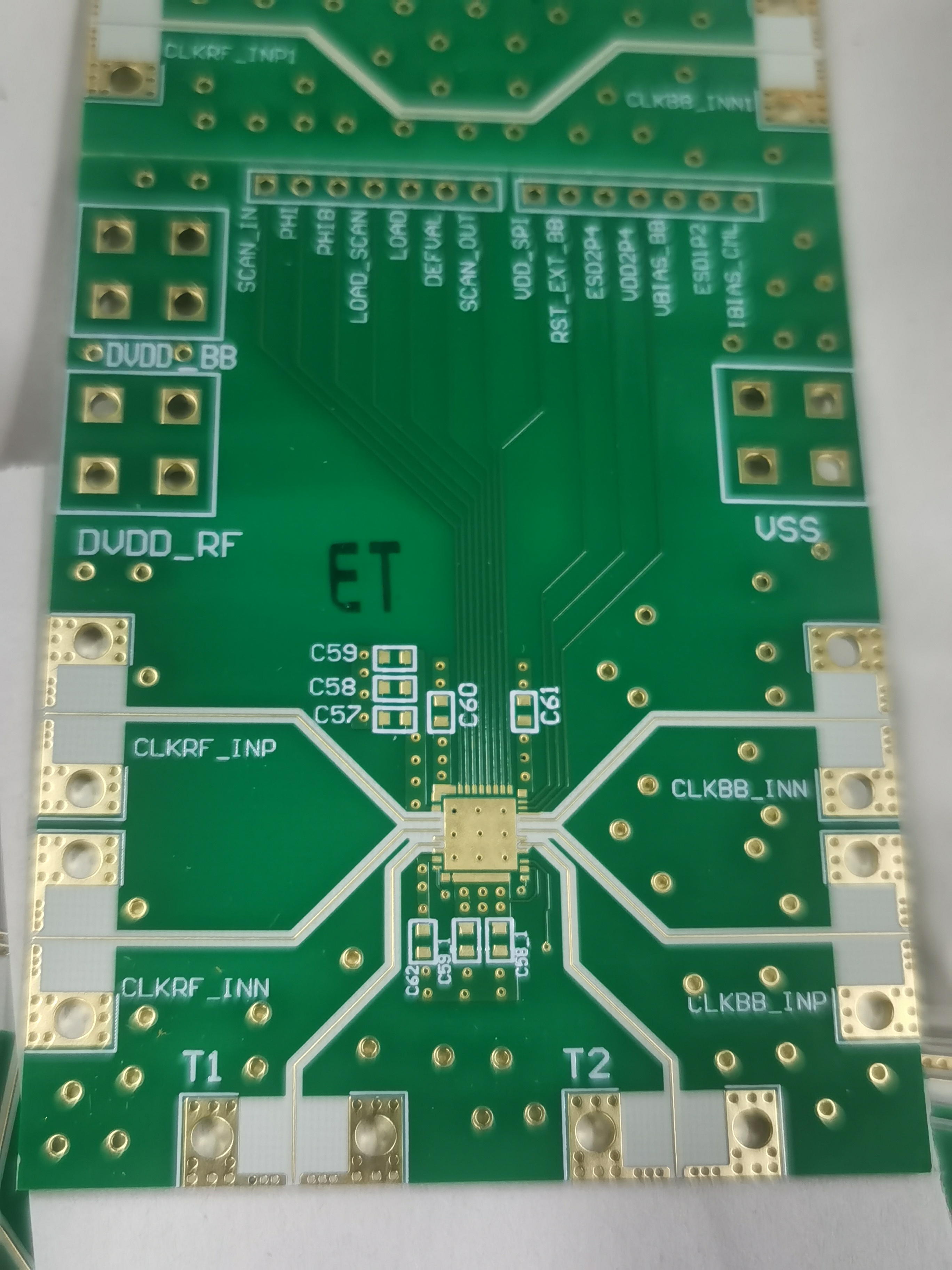

ENEPIG for RO4350B with blind vias from L1-L2,L3-L4

ENEPIG for RO4350B with blind vias from L1-L2,L3-L4¥ 0.00Buy now

-

4.4mm PCB with blind vias and countersink holes

4.4mm PCB ,4 Layer

Blind vias L1-L2 ,L3-L4

Countersink holes

Matt Black solder mask

Via in pad

12:1 (Thickness :min hole)¥ 0.00Buy now

-

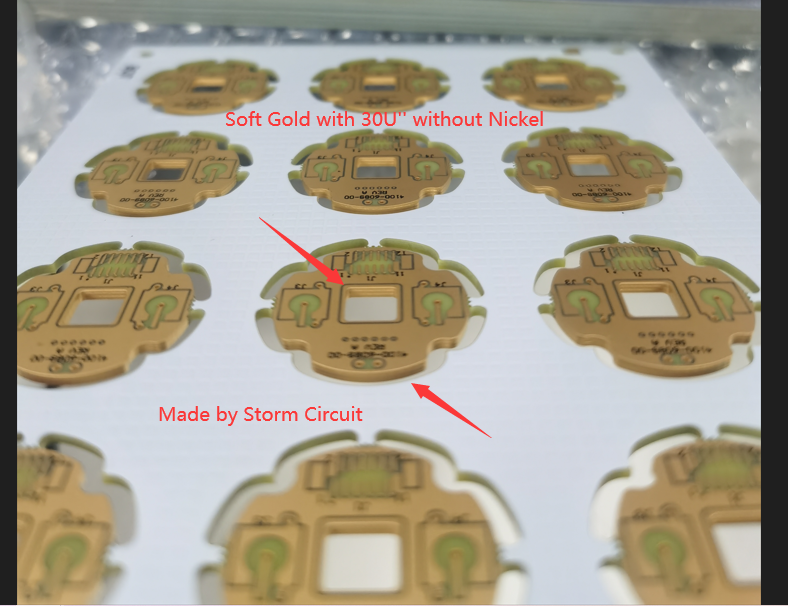

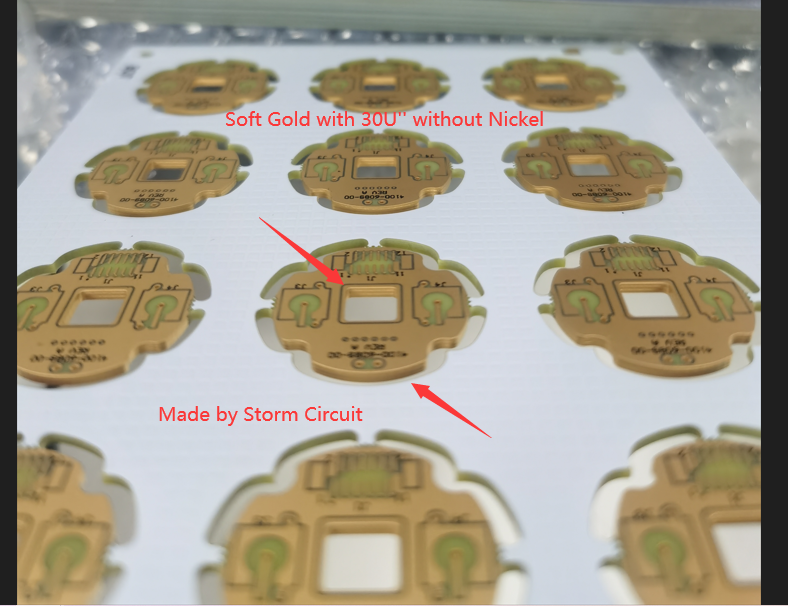

Soft Gold plating with 30 Micro inch PCB

FR4 :4 layer 1.6mm 1oz

Full gold at top and bottom side in units

Soft Gold with 30 micro inch

Edge plating

Black solder mask,white silkscreen¥ 0.00Buy now

-

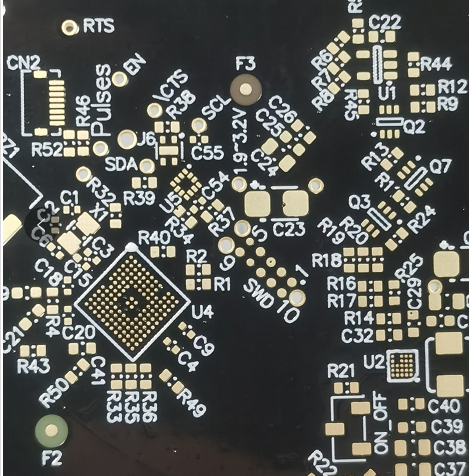

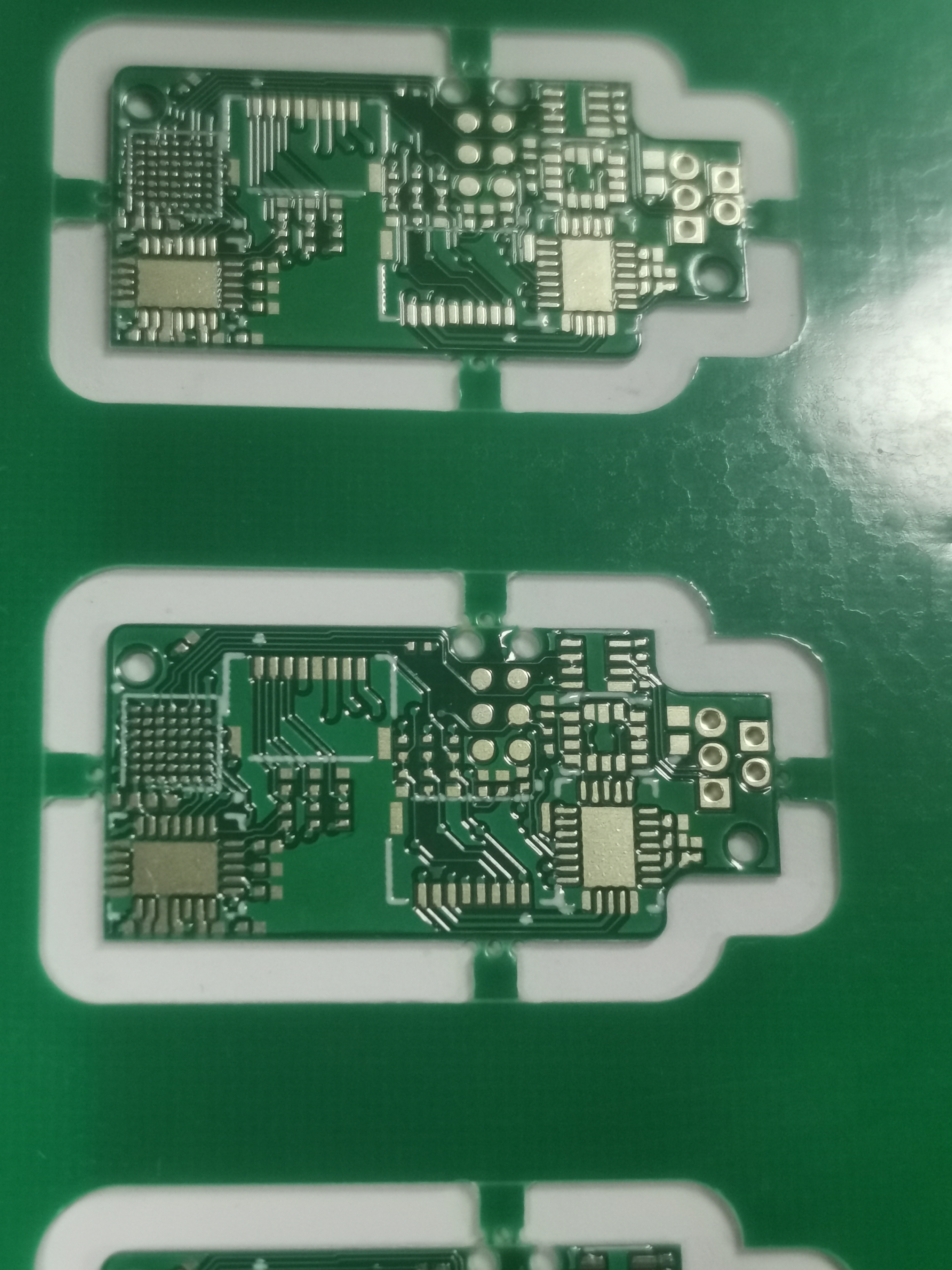

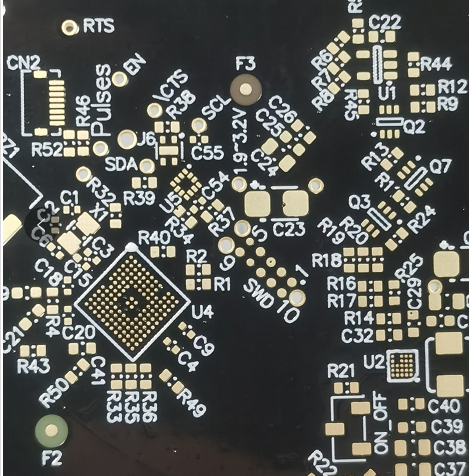

0.4mm pitch BGA PCB with 0.1/0.1mm

0.4mm pitch BGA

BGA pad 0.2mm

4 layer 1.6mm

min trace/space 0.1/0.1mm¥ 0.00Buy now

-

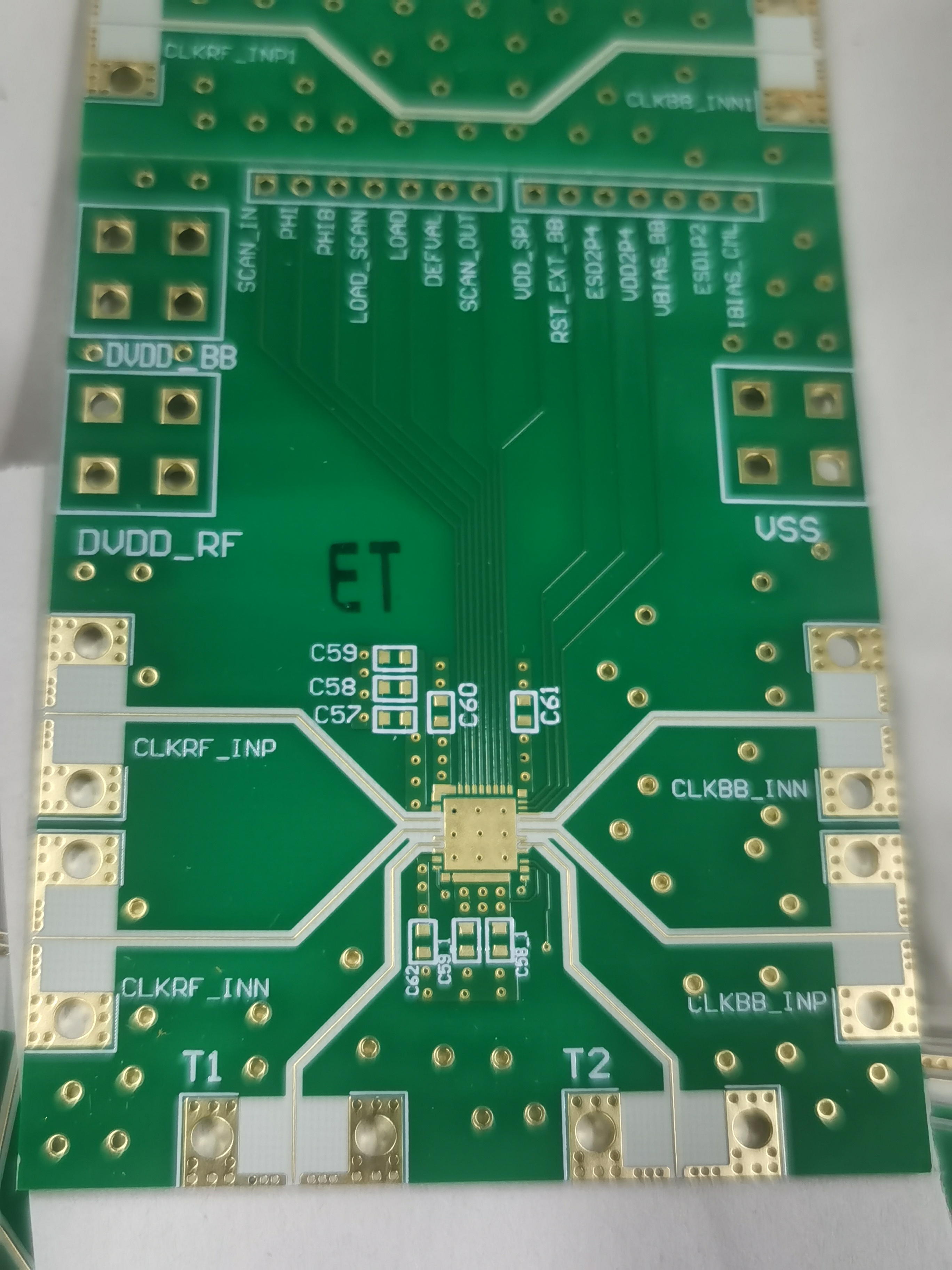

10 layer RF PCB with RO4350B+FR4

10 layer RF PCB with RO4350B+FR4

Blind vias L1-L2,L9-L10

Via in pad ,POFV

RO4350B 6.6mil¥ 0.00Buy now

-

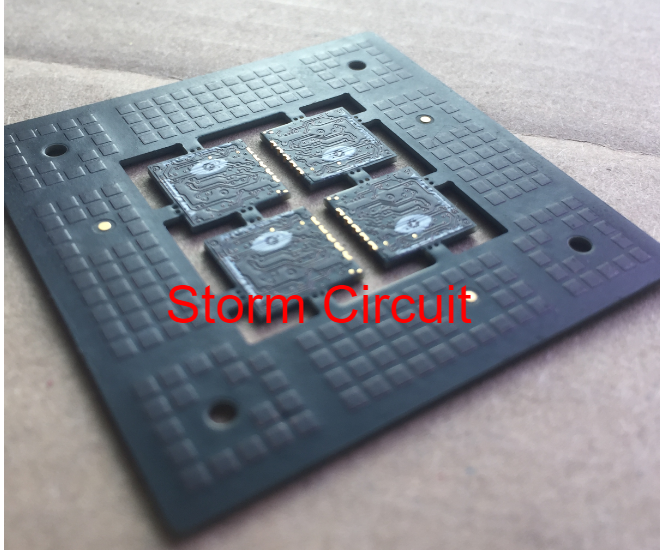

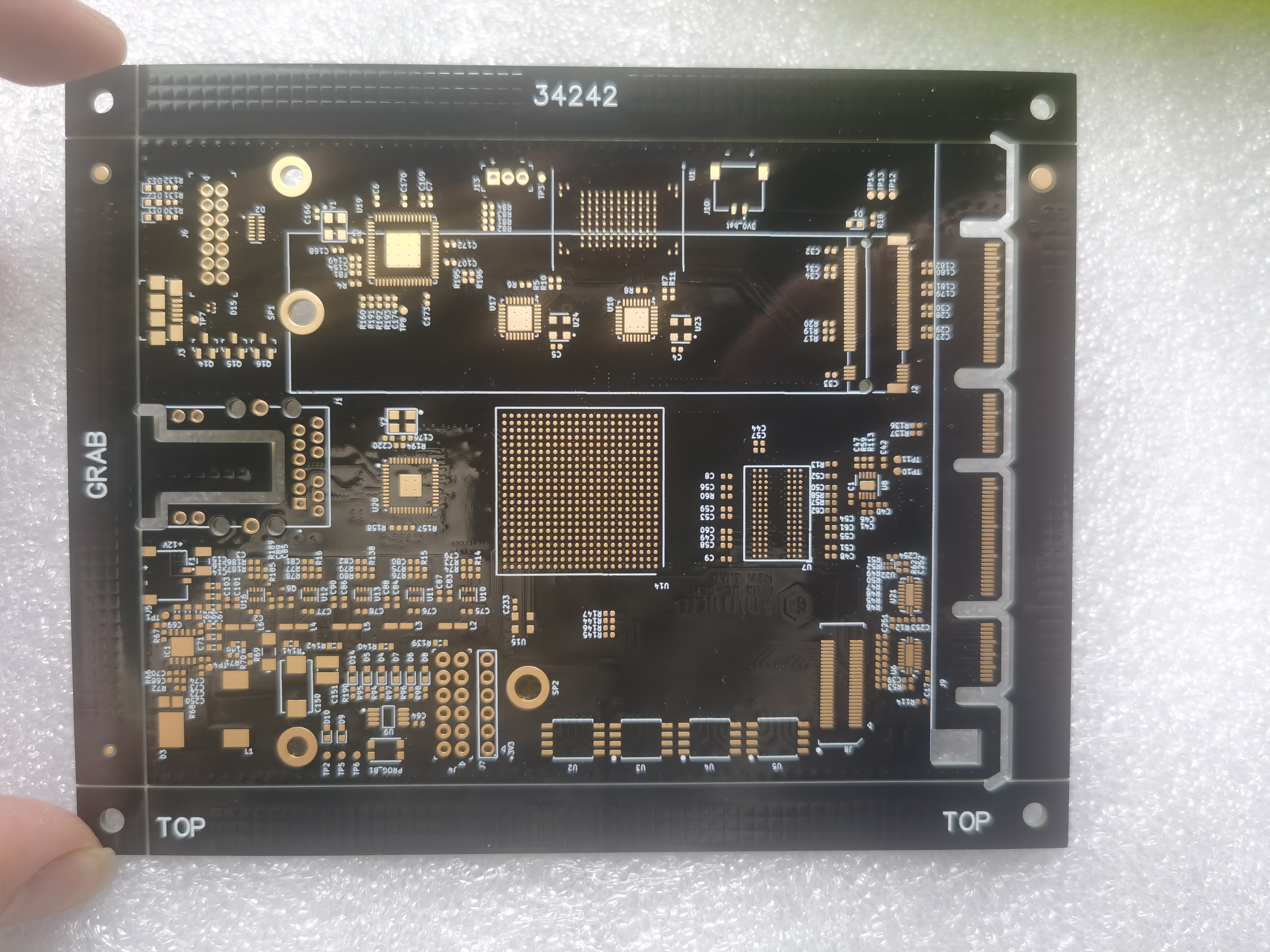

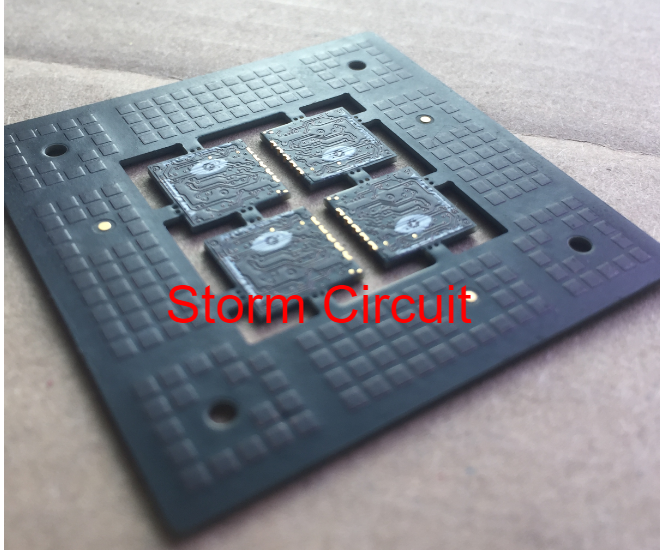

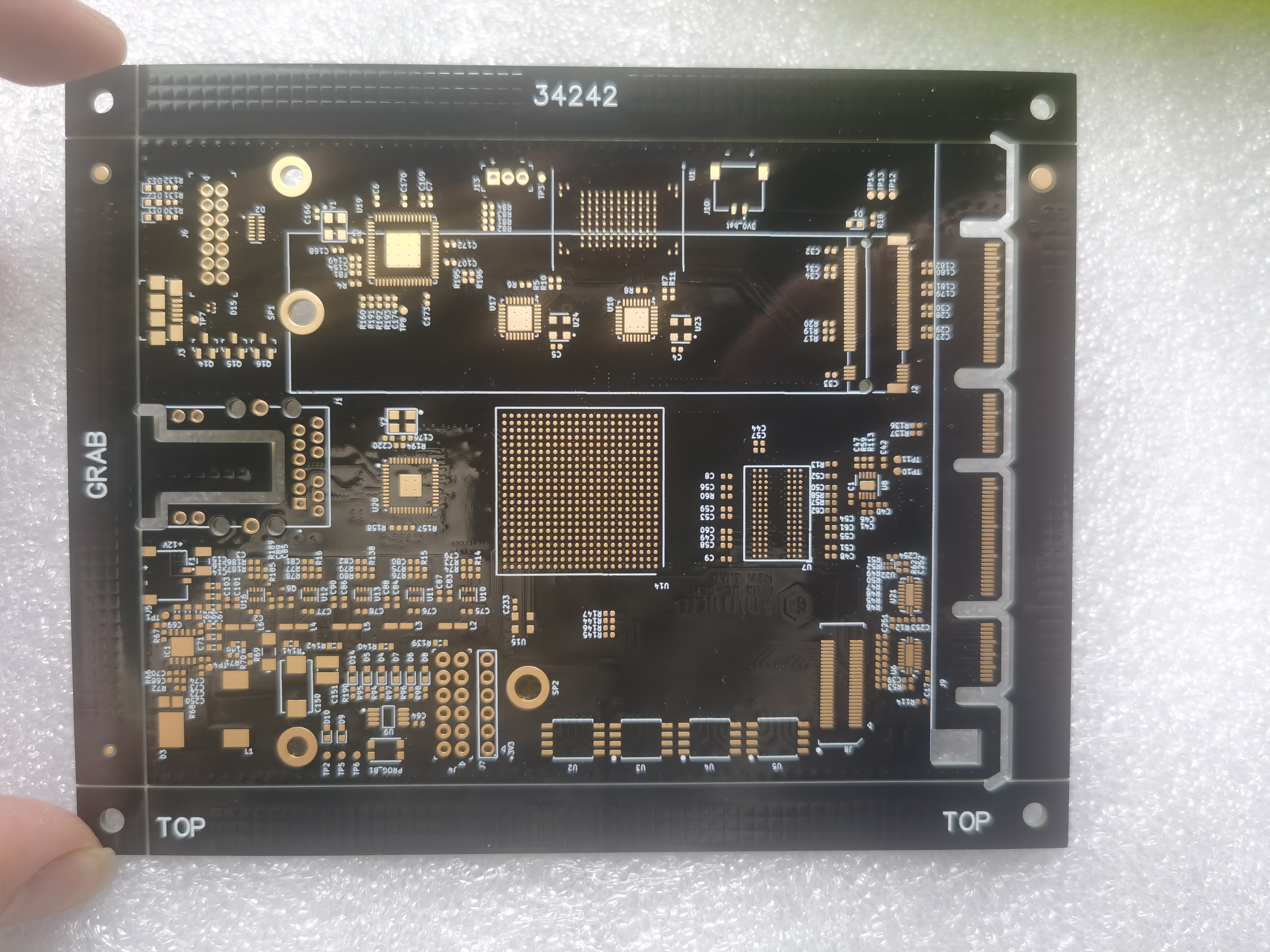

L1-L2,L1-L3,L1-L6 8 layer HDI PCB

L1-L2,L1-L3,L1-L6

8 layer HDI PCB

Laser drilling

PCB material:TU-768, TG170

Via in pad¥ 0.00Buy now

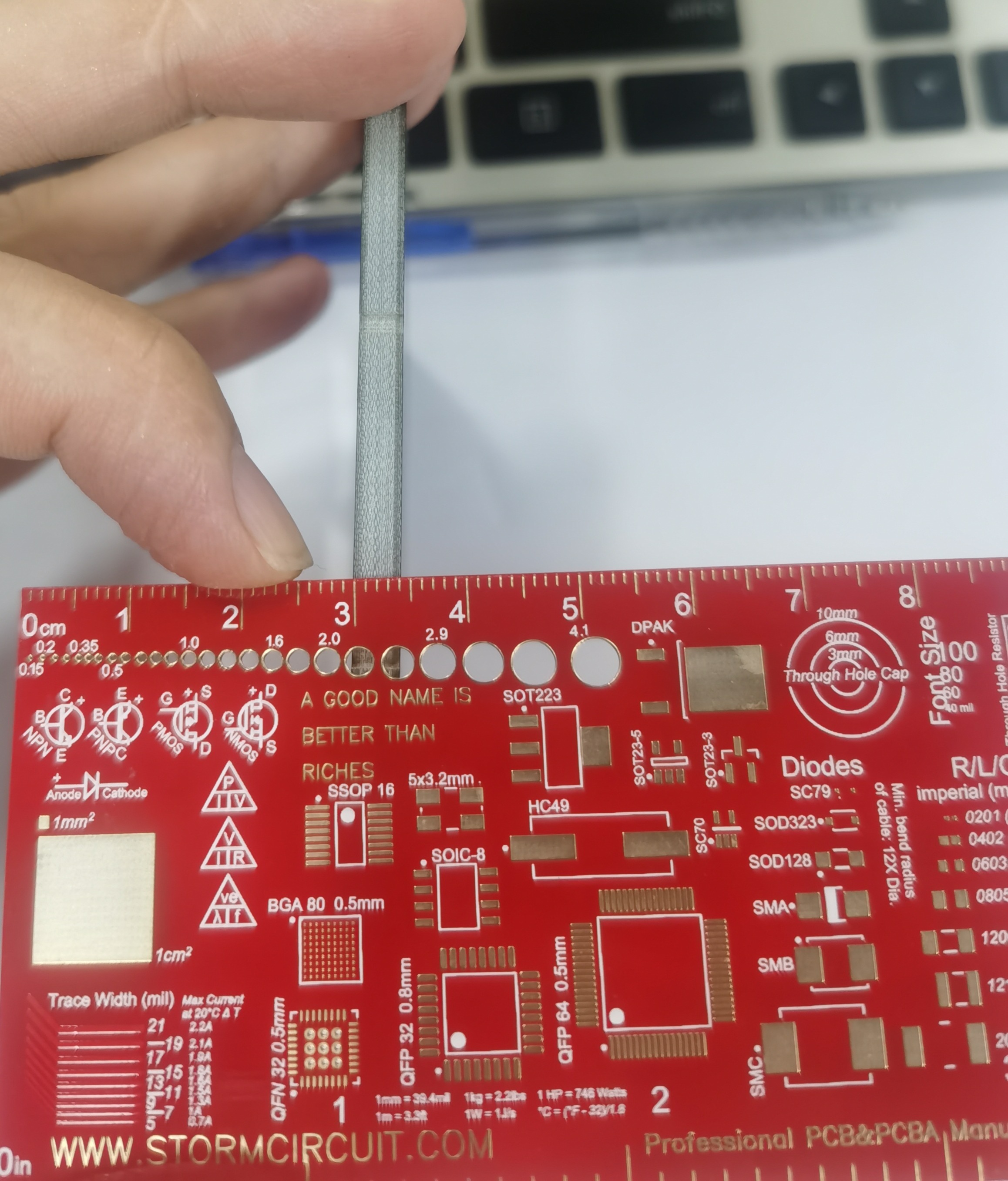

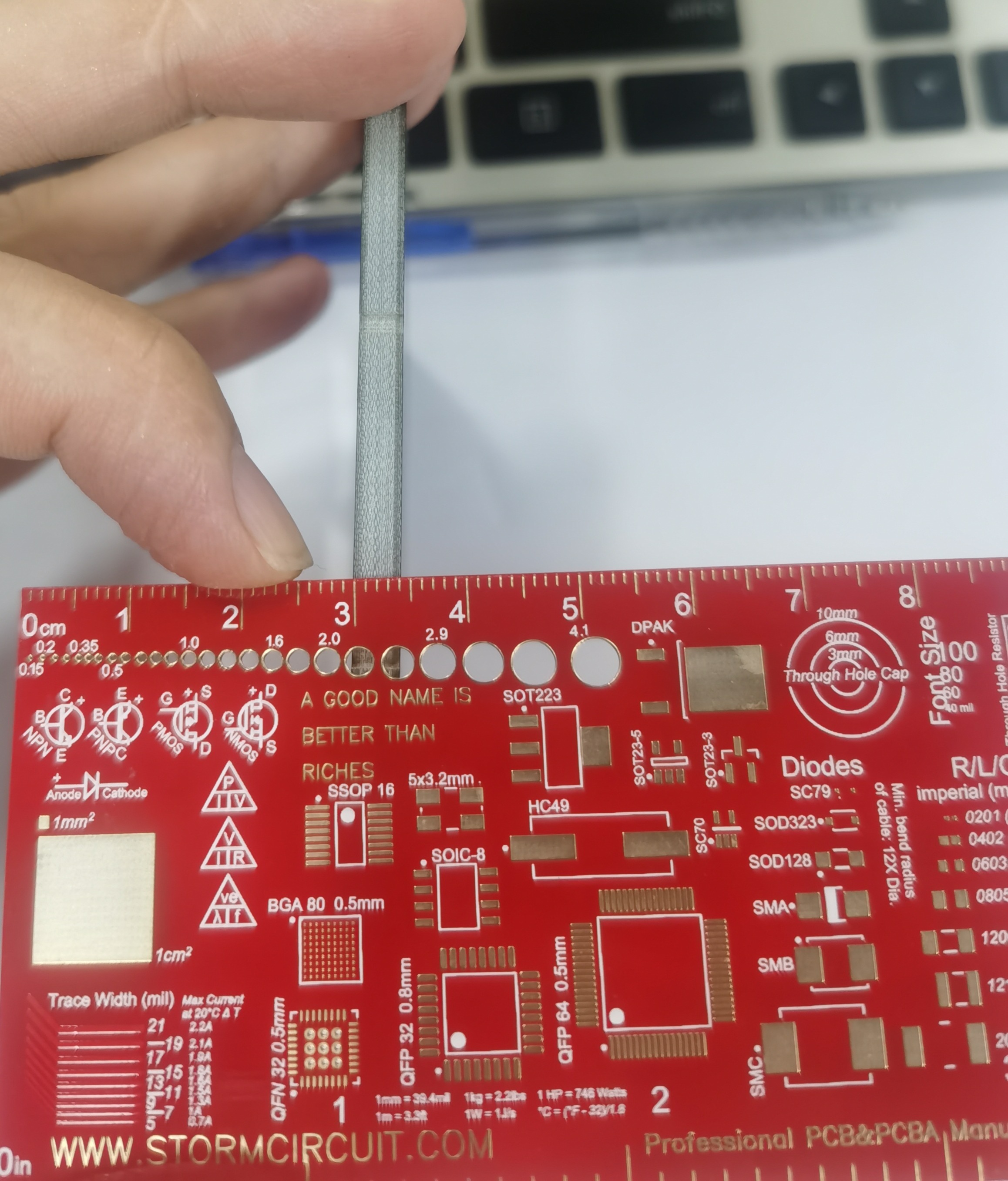

Our HDI PCB products

HDI PCBs capitalize on the latest technologies available to increase the functionality of PCBs using the same or less amount of area. This advancement in PCB technology is driven by the miniaturization of components and semiconductor packages that supports advanced features in revolutionary new products such as touch screen computing and 4G network communications,now it is 5G time,any layer technology is required for PCB .

HDI PCBs are characterized by high-density attributes including laser microvias, fine lines and high performance thin materials. This increased density enables more functions per unit area. Higher technology HDI PCBs have multiple layers of copper filled stacked microvias (Advanced HDI PCBs) which creates a structure that enables even more complex interconnections. These very complex structures provide the necessary routing solutions for today's large pin-count chips utilized in mobile devices and other high technology products. Most HDI boards are with burried/blind vias from 0.076-0..127mm.

Vias for HDI is 3-5 mil (0.076-0.127mm),line width is from 3-4mil(0.076-0.1mm). 0.8mm /0.5mm pitch BGA is usually for 1+N+1. Another thing is many customers did not know HDI board have to use special material--RCC (Resion Coated Copper),0.08mm thickness with copper.

0.4mm pitch BGA, means the space from BGA ball to another BGA ball is 0.4mm.

Many PCB designers do not know much how to design 0.4mm pitch BGA board,they make things very difficult to do .Here is a 0.4mm pitch BGA PCB design guide from TI OMAP processor. Pages 8 through 12 talk about pads, mask and vias. Obviously, you should consult similar materials written specifically for the part you are using, but Ti did a great job of covering all the issues here

Gerber file for 6 layer HDI board.

Specification:FR4,TG170,1.2mm,1oz for all layers.

min via:0.15mm, min trace/space:0.1/0.1mm.

Impedance control,

Black solder mask,ENIG

Blind/burried vias (L1-L2,L1-L3,L4-L6,L5-L6)

HDI example

- 2022-06-23

Storm Circuit Technology Ltd, Made in China with Love.

2009-2022