-

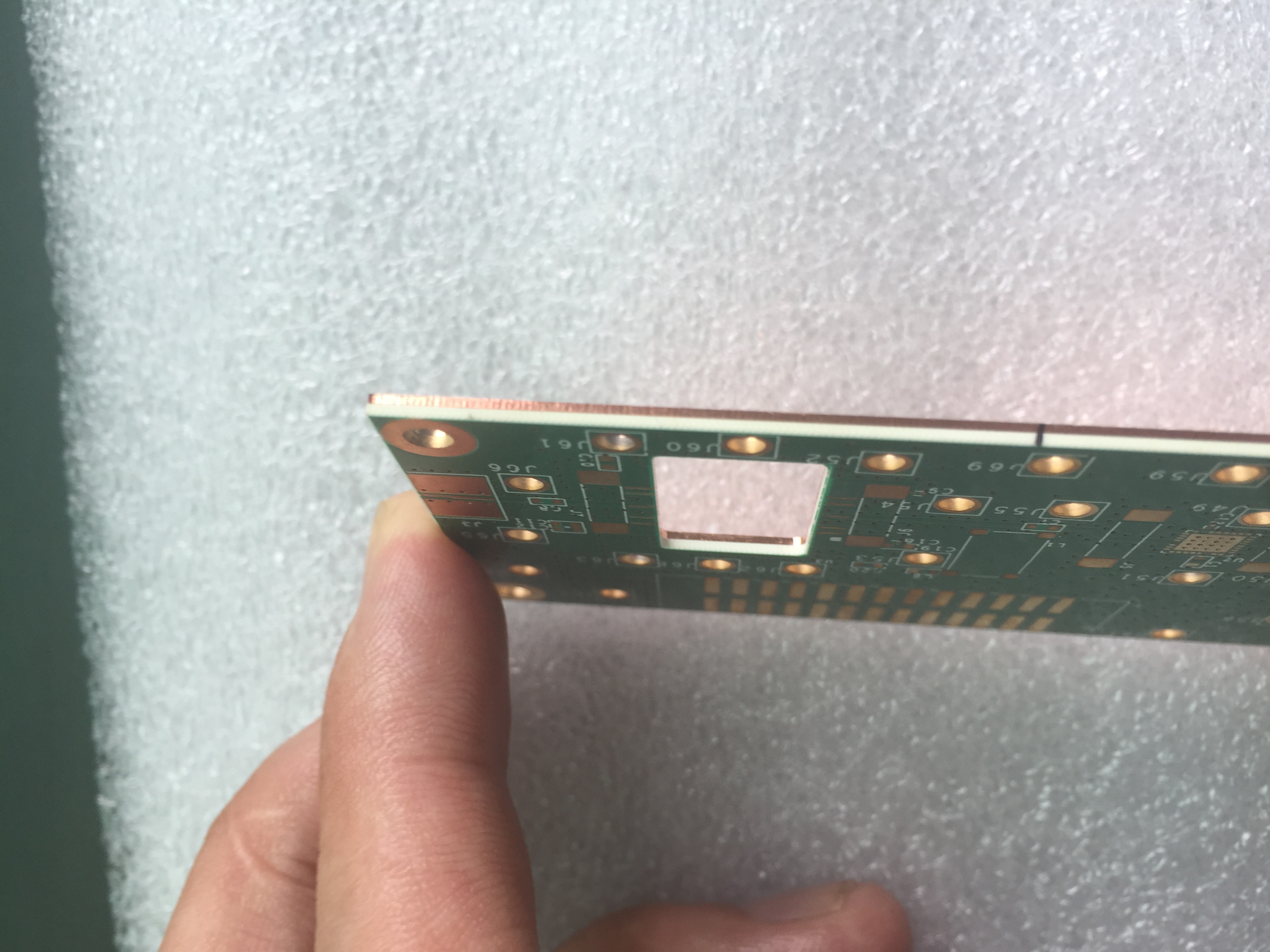

Thermoelectric separation copper substrate PCB---highest thermal conductivity with 380W/mk

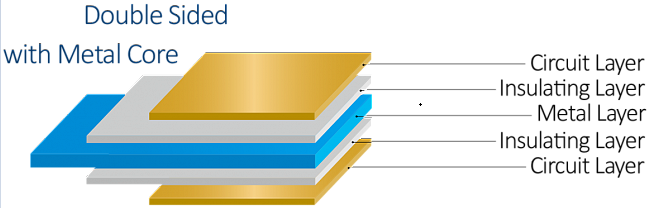

2 layer double sided copper core PCB

ENIG

White solder mask, Blue silkscreen.¥ 0.00Buy now

-

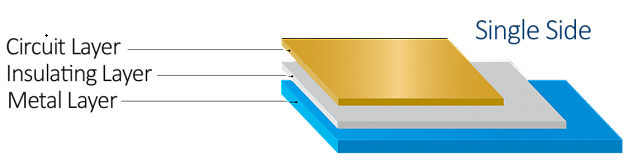

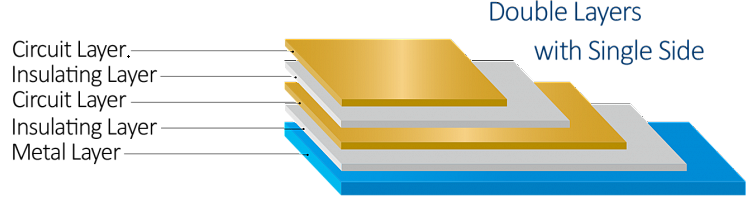

Sinlge layer Aluminum PCB

Sinlge layer Aluminum PCB--Metal Core PCB

Thickness 1.6mm

Black solder mask

White silkscreen

ENIG

Thermal conductivity:1.0W/mk¥ 0.00Buy now

-

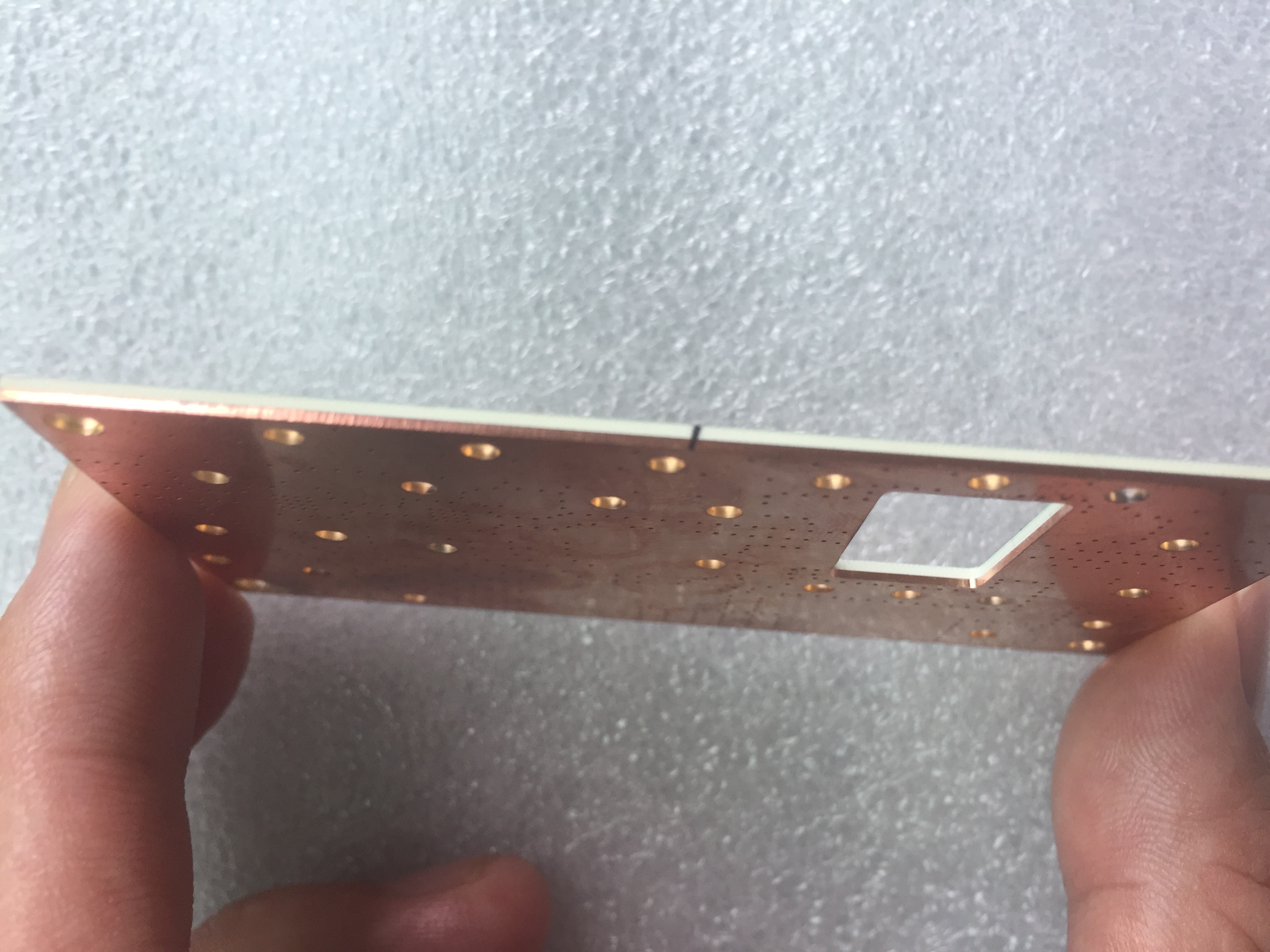

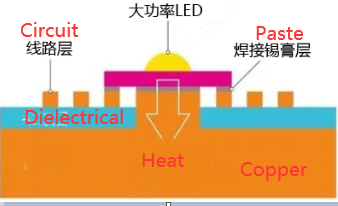

Metal core PCB with copper core

Metal core PCB with copper core

one layer PCB

Copper Core

High thermal conductivity PCB

Thermal conductivity:400 W/m.K

1.6mm thickness

Immersion Gold¥ 0.00Buy now

-

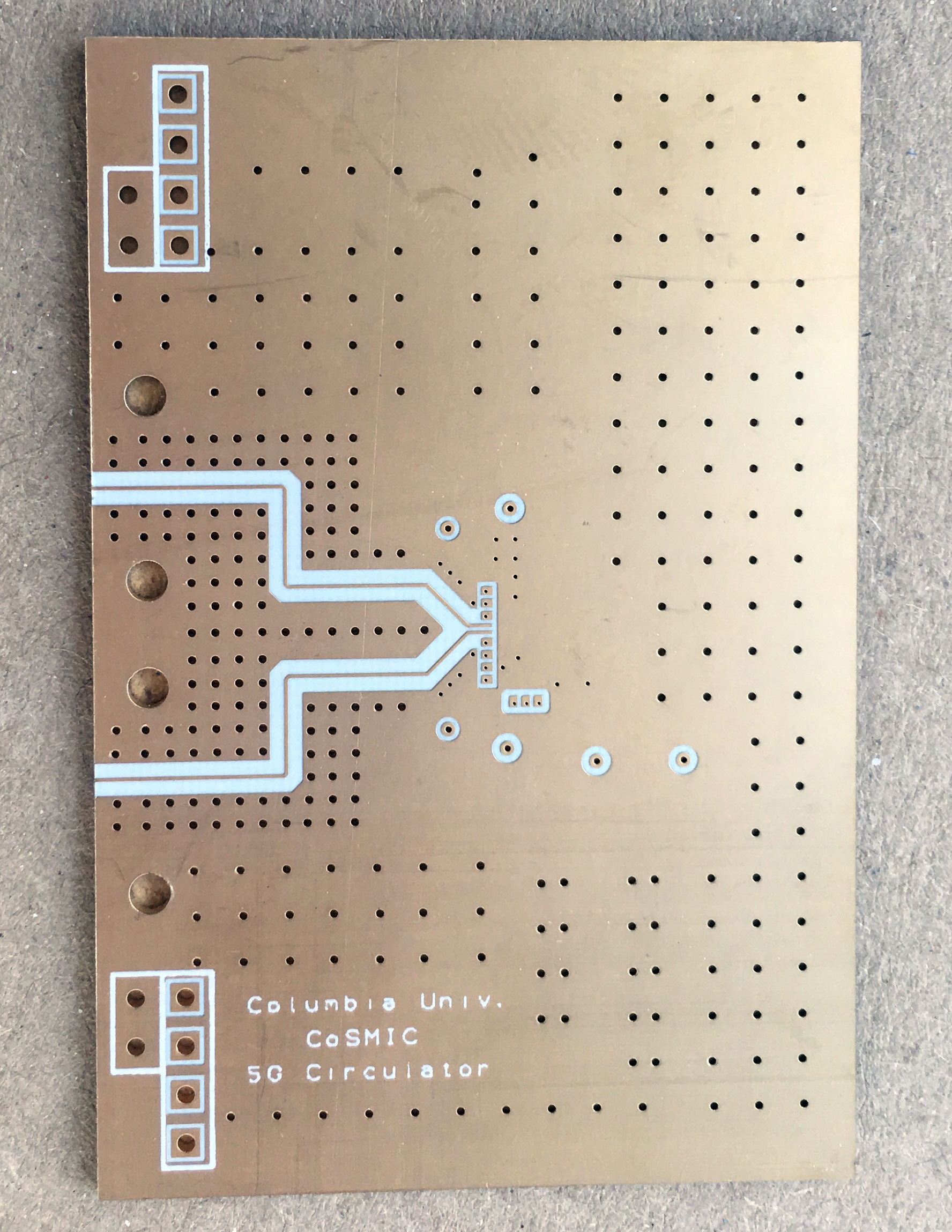

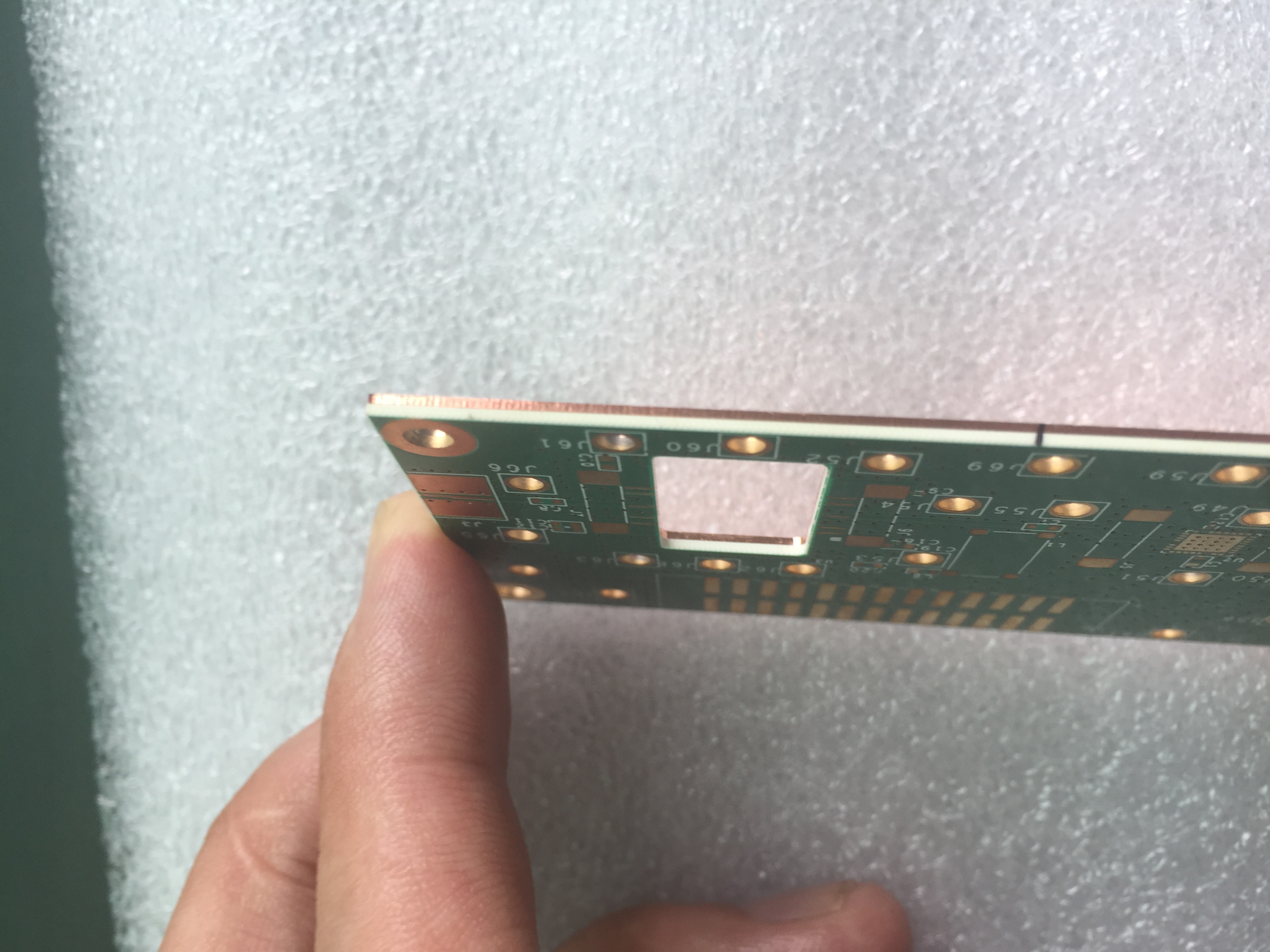

Copper Core PCB

Copper Core PCB ,a type of metal core PCB

Layer:2 Thickness:1.6mm

Thermal conductivity:400 W/m.K¥ 0.00Buy now